Payment Type:T/T

Incoterm:FOB,CFR,CIF,EXW

Min. Order:1 Set/Sets

Transportation:Ocean

Port:Shanghai

Model No.: Finned Tubes

Place Of Origin: China

Optical Tube Size /dxs: ∅25.4x2.11

Light Tube Material: SA179 K01200

Fin Material: AL 1060

Finned Shape: Spiral fin tube, square fin tube, etc

Use: Water wall, economizer, air preheater, industrial waste heat recovery, air cooler, etc

Packaging: Modules are shipped in bulk/packaged

Transportation: Ocean

Port: Shanghai

Payment Type: T/T

Incoterm: FOB,CFR,CIF,EXW

Steam Heating Or Heated Exchange Finned Tube Exchanger

Product introduction

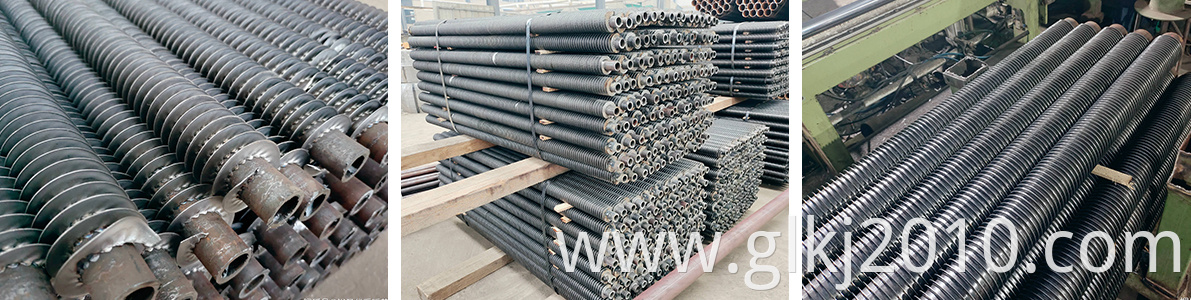

Heat Exchange Spiral Finned Tube A finned tube is a heat transfer device consisting of a set of parallel metal fins and internal tubes. Heat Exchange Finned Tub Heat transfer Liquid or gas flows in the tube and through contact with the fin, heat is transferred to the fin and then transferred to the surrounding environment by convection and radiation.Finned Tube Heat Exchanger,Heat Exchange Spiral Finned Tube Finned Tube Heat Exchanger Finned tube is mainly used in air cooler, automobile radiator, steam radiator, air conditioner and industrial heater and other fields. Its advantages include efficient heat transfer, small space and light weight.

Product parameter

Optical tube size /dxs:∅25.4x2.11

Light tube material:SA179 K01200

Fin material:AL 1060

Finned shape:Spiral fin tube, square fin tube, etc

Use:Water wall, economizer, air preheater, industrial waste heat recovery, air cooler, etc

Finned tube production process:

1, raw material inspection:

1.1 steel pipe inspection (caliber, wall thickness, length, material, pit, crack, straightness, etc.);

1.2 Steel strip inspection (material, width, thickness, notch, fold, etc.);

2, product sample:

2.1 Record winding current voltage, speed, high frequency parameters, sample physical experiment, test outsourcing, pull rate, fusion rate;

2.2 Make process evaluation according to qualified sample parameters;

3, production:

3.1 steel pipe rust, cutting allowance, groove processing;

3.2 Production winding, first inspection (appearance, outer diameter, fold, fin length, spacing, etc.);

3.3 Production and winding, 500 pieces shall be checked in the middle;

3.4 Production winding and final inspection;

4, Rust prevention and packaging.