Payment Type:T/T

Incoterm:FOB,CFR,CIF,EXW

Min. Order:1 Set/Sets

Transportation:Ocean

Port:Shanghai

Model No.: Finned Tubes

Place Of Origin: China

Optical Tube Size /dxs: ∅25.4x2.11

Light Tube Material: SA179 K01200

Fin Material: AL 1060

Finned Shape: Spiral fin tube, square fin tube, etc

Use: Water wall, economizer, air preheater, industrial waste heat recovery, air cooler, etc

Packaging: Modules are shipped in bulk/packaged

Transportation: Ocean

Port: Shanghai

Payment Type: T/T

Incoterm: FOB,CFR,CIF,EXW

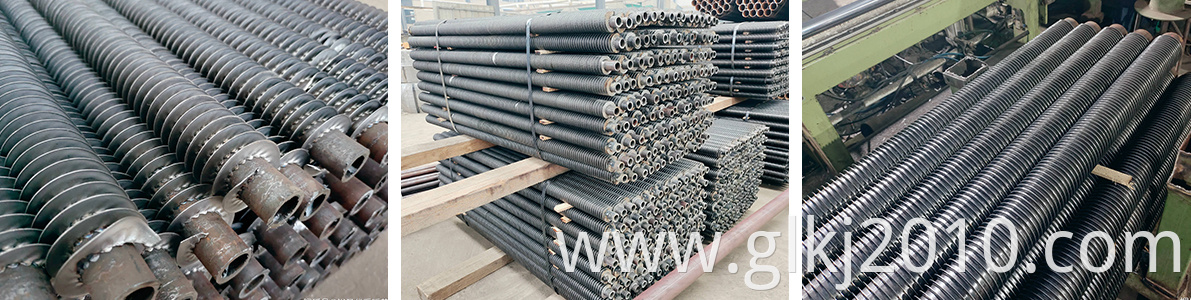

Spiral Fin Stainless Steel Tube Cooling Pipe

Product introduction

In 2016, Jiangsu Glan Environmental Technology Co., Ltd. introduced the new 4 generation of high frequency welding screw finning machine produced by South Korea JTC Company, 2 new equipment, 1 4 inches, 1 8 inches. At present, 8 inches is the only large caliber imported equipment in China; The longest length can produce 27 meters, reduce the connection point, so that the installation is more economical and fast; Finned tube for finned and steel pipe winding full contact welding, fusion rate up to 95%, tensile strength up to 300mpa above, improve the heat dissipation area, improve efficiency; Various welding materials, the current production materials include carbon steel, P11, P5, P91, 304H, 347H, 800H, 600H, and in the dissimilar steel welding has also made great progress.Heat Exchange Finned Tube,Finned Tube Heat Exchanger,Heat Exchange Spiral Finned Tube

Product parameter

Optical tube size /dxs:∅25.4x2.11

Light tube material:SA179 K01200

Fin material:AL 1060

Finned shape:Spiral fin tube, square fin tube, etc

Use:Water wall, economizer, air preheater, industrial waste heat recovery, air cooler, etc

Finned tube production process:

1, raw material inspection:

1.1 steel pipe inspection (caliber, wall thickness, length, material, pit, crack, straightness, etc.);

1.2 Steel strip inspection (material, width, thickness, notch, fold, etc.);

2, product sample:

2.1 Record winding current voltage, speed, high frequency parameters, sample physical experiment, test outsourcing, pull rate, fusion rate;

2.2 Make process evaluation according to qualified sample parameters;

3, production:

3.1 steel pipe rust, cutting allowance, groove processing;

3.2 Production winding, first inspection (appearance, outer diameter, fold, fin length, spacing, etc.);

3.3 Production and winding, 500 pieces shall be checked in the middle;

3.4 Production winding and final inspection;

4, Rust prevention and packaging.